Chumba Frame Building

Each design seeks perfect balance: Blending toughness with light weight, compliance with high performance.

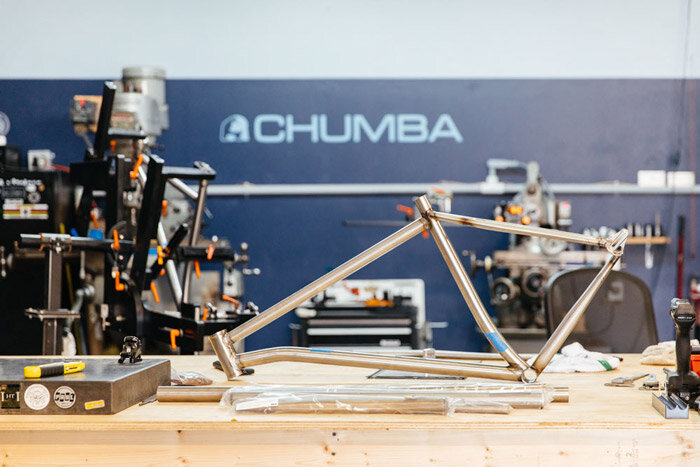

Chumba frames are built with double butted steel or aerospace grade 3AL-2.5V titanium from the world’s leading manufacturers. Each frame starts as a batch of tubes that matches a carefully planned & prototyped build of materials. Tube dimensions and thickness are chosen per model & size to achieve the perfect ride quality. Check out our video below to see how we do it!

We always use a few guiding principles:

Material Ethos

We select materials based on a variety of factors. Starting with the highest quality options and then distilling the build of materials to fine tune the ride quality we are looking to achieve.

Materials used provide durability, predictable tracking through technical terrain, comfort and power transfer.

Oversized chain-stays to ensure everything you put into the bike gets transferred into the trail and is stable loaded down.

Oversized tubing make for strong tube junctions and allow a deeper tuning of frame compliance.

Threaded bottom brackets only.

Steel

Steel MTB's get our bent double-butted down tube to strengthen the steering junction by supporting the head tube from impacts on the trail more horizontally then a straight tube would.

Stainless steel dropouts to dramatically increase frame strength at the dropout.

All of our bikes use a selection of tubes from the industries leading manufacturers. We blend our tubesets so we can pick the ideal tube for each location on the frame, vs. limiting ourselves to just one brand offering.

We use tubes from Columbus, Dedacciai, Tange, Variwall and Paragon Machine Works.

Titanium

Our Sendero, Yaupon and Terlingua SL frames all use domestically sourced and certified aerospace grade 3Al-2.5V titanium tubing.

Our mountain bikes all use a 1.75”/44.45mm straight down tube. This size tube both offers the ideal strength, miter size and clearance for suspension forks. On some small frames we run 1 size down for added compliance on the smaller frame.

We believe in appropriately sizing tubes for each size. So typically you will see sizes small and medium run a smaller top tube diameter then our large and XL frames. Some models we also change the seat stay diameter per size.

6/4 titanium sliding dropouts to dramatically increase frame strength at the dropout.

Our Ti Space Yoke on the Sendero and Yaupon model is a 3-d printed or additive frame component we designed specifically to increase compatibility between tire sizes, chainring and crank offerings. Notably the design allows us to offer some of the best tire clearances out there on the biggest chainstay diameter, 22.2mm.

Ti Space Yoke’s are made in USA of 6/4 Ti. They are FEA strength tested and heat treated to Rolls Royce Certified to aerospace specifications.

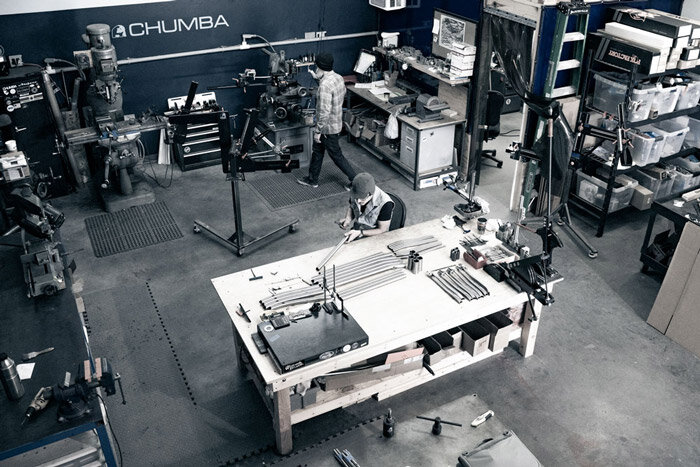

Process

We believe in building beautiful, functional handmade bikes that offer incredible compatibility & performance for all riders.

We build in small batches to ensure the highest quality & focus on each individual frame.

Clean, clean, clean. Every tube, steel or titanium goes through an extensive cleaning process to ensure the purest welds.

Custom rear triangle bends and profiles per size/model for maximum tire compatibility.

All frames are argon purged & welded with heat sinks in place to prevent material thinning & distortion.

Precision tube miters that fit together like a socket.

Each design is tirelessly prototyped & race proven by our diverse team of international riders.